The OXE diesel outboard was designed specifically for commercial users has been well received, according to Luke San Antonio, commercial marine market manager at Mack Boring & Parts Co., Somerset, N.J., which sells OXE outboards.

The only shortcoming has been its limited power range — 125 hp to 200 hp. “Operators were always looking for more power and speed. We were kind of limited,” said San Antonio. Not anymore. An OXE 300-hp outboard with an aluminum 3-liter BMW block was recently unveiled. Mack Boring is expecting its first 300-hp outboard demo model by the end of February and the first 300 hp to sell by the end of March.

For some workboat operators, outboards have been on what San Antonio refers to as “the no-go list.” That’s especially true for ferry operators because regulations restricted the use of gasoline for safety reasons. But the OXE outboards “open it up for these guys to explore diesel outboards.”

Torque and fuel savings are two advantages that come with the OXE outboards. The OXE 300 should have a fuel burn 45% to 50% lower than a gasoline-powered outboard. The torque with an OXE 300 at 1,750 rpm is 502 ft. lbs., “which is quite good,” said San Antonio, and it allows you to swing a bigger prop.

That should be attractive to workboat operators that have been powering with inboard/outboard stern drives. San Antonio said switching from inboard/outboards to diesel outboards “makes a little more sense in terms of weight and you are freeing up a bunch of space internally for storage and passengers.” He also notes that if enough weight can be saved when repowering with diesel outboards, a vessel could be certified to carry additional passengers. When an engine needs to be replaced, it’s much easier to switch out an outboard then an engine mounted inside the hull.

The Coast Guard has noticed the advantages with an OXE outboard on the transom.

A couple of years ago, the Coast Guard entered into a research and development agreement with Mack Boring that tested the 200-hp OXE on the back of one of the Coast Guard 29' RB-S-class boats built by Safe Boats International. The outcome was successful enough that the Coast Guard ended up purchasing four OXE 200s for RB-S vessels.

A unique feature about the diesel-powered OXE compared to a gasoline outboard is the gas outboard runs seawater through the entire cooling circuit, while the OXE runs seawater through the heat exchanger but not the block. “So, corrosion is not much of a concern,” said San Antonio.

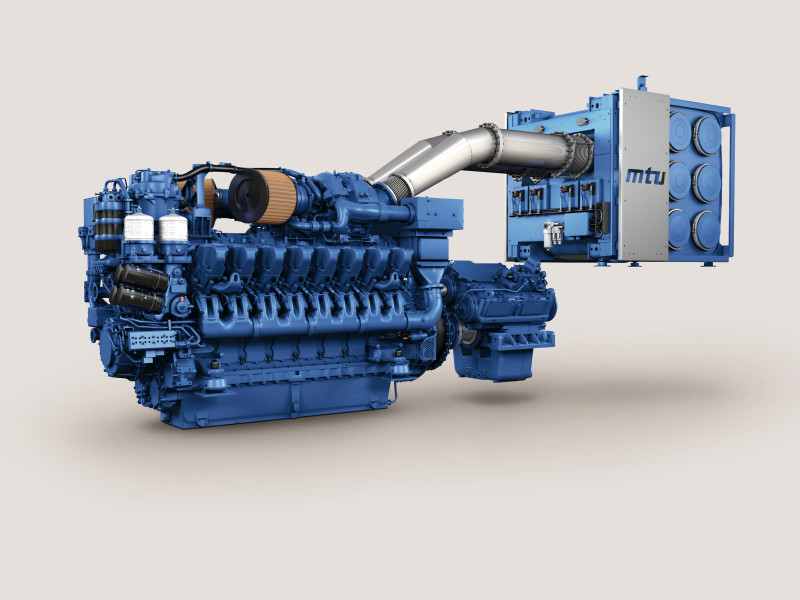

MTU

In January, Rolls-Royce’s MTU 16V 4000 diesel achieved Tier 4 certification. That’s after more than five years and 10,000 hours field-testing 10 MTU 16V 4000 engines with SCR units. Six of the 3,430-hp engines were on three WETA (Water Emergency Transportation Authority) ferries (two engines per ferry), while two Foss Maritime tugs were each powered by a pair of the MTUs.

“All 10,000 hours have been without major incident,” said Jeff Sherman, MTU of America’s senior sales manager.

One of the WETA ferries that tested the engines was the Dakota Creek Industries-built 142', 445-passenger Pyxis, that operates in San Francisco Bay. The MTU 16V 4000 power package with its SCR unit powered the Pyxis up to 34 knots, while registering a 75% reduction in NOx emissions compared to IMO Tier II, and a 65% reduction in particulates compared to EPA Tier 3.

Putting together the Tier 4 package was a combined effort between Dakota Creek in Anacortes, Wash., the design team at AMD Marine Consulting in Australia, and MTU engine experts from Rolls-Royce in Germany. Driving the design effort was the idea of “not taking up any more space than absolutely necessary while still meeting all the criteria governing add-on modules and ease of maintenance,” said Sherman.

Engine improvements that came about as a result of the work included an optimized turbocharging system and better fuel efficiency, while accommodating significantly higher exhaust back pressure for exhaust aftertreatment optimization. The MTU Smart Injection was also introduced. It’s a continuously self-monitoring and self-compensating fuel injection system ensuring stable low-emission behavior and engine performance.

Delivery of the Tier 4-certified MTU Series 4000 engine should begin later this year. It’s also possible some MTU 12V 4000 ratings will achieve Tier 4 status later in the year.

The MTU 16V 4000 certification is a bit of a milestone in that it’s only the second high-speed diesel to gain the Tier 4 rating. “In Germany they call it the Champions League,” said Jennifer Riley, MTU’s senior manager, marketing and communications, “because it’s the highest standard for emissions in the world.”

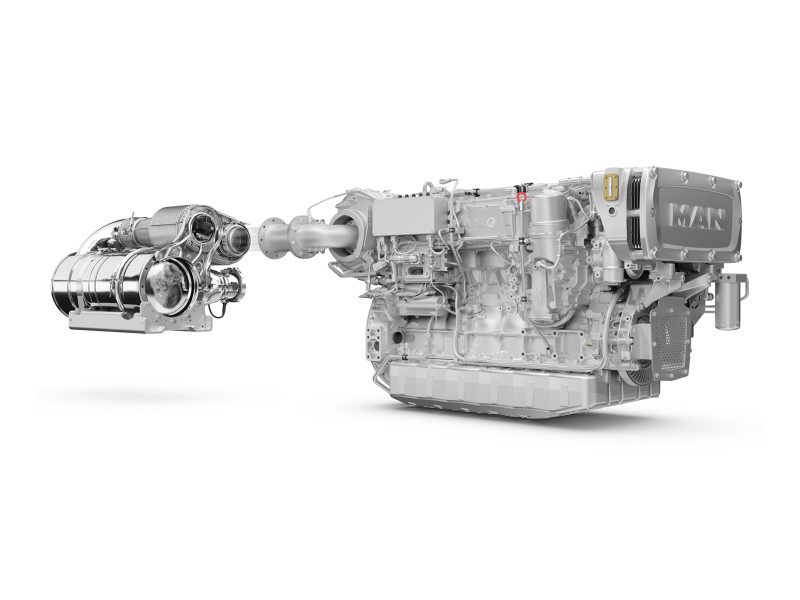

MAN

MAN has added five new power ratings — 394 hp, 450 hp, 500 hp, 560 hp and 600 hp — to its D2676 diesel lineup that meet IMO Tier III and EPA Tier 4 requirements. These engines are especially targeted at wind farm vessels, patrol boats, passenger boats, pilot boats and ferries, said Axel St. Aubin, MAN’s director of off-road engines and certification.

The engines qualified for the Tier III rating with the use of MAN’s SCR catalytic converter. The SCR unit, which removes nitrogen oxide from the exhaust gases, doesn’t take up excessive space.

“We paid special attention to making it compact and flexible,” said St. Aubin. That allows for different installation options depending on the size of the engine room. Of course, with the SCR unit, the standard diesel engine’s muffler is no longer needed.

You do need a small tank for the reducing agent, which is a urea solution. The tank is 10% the size of the diesel fuel tank. Fitting the tank into an engine space “has not been an issue,” said St. Aubin.

Workboat operators who are not familiar with SCR aftertreatment systems on marine engines but might have heard about off-road and on-highway issues with aftertreatment systems — as the reducing agent is diminished the engine loses power — need not worry. Losing power would be a dangerous situation if you were maneuvering through a congested harbor or approaching a bridge while towing a barge, but in a marine situation, “the engine will not cut power,” said St. Aubin. A diminished reduction agent “will have no effect on the engine output.”

Looking ahead, St. Aubin said MAN is working on hydrogen power, which is in the “early stages but looks promising.” Another venture is hybrid-electric power. MAN is working with “a modular system where one or two modules go between the gearbox and the engine.” That’s in the early development stages.

Well past the early development stages are the five new power ratings for the D2676 MAN diesels. There’s no waiting period. “If you want one it’s readily available,” said St. Aubin.

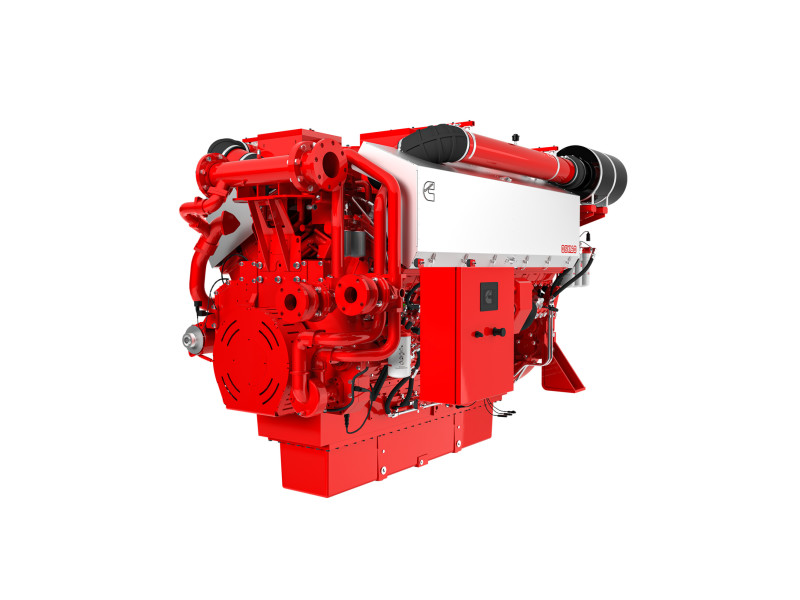

CUMMINS

Cummins is upgrading its engine lineup with an EPA Tier 4/IMO Tier III version of the QSK60 and a new B4.5. The QSK60 was scheduled to be introduced at the 2020 International WorkBoat Show, which was cancelled due to Covid-19. Now both engines will be introduced on March 23.

The QSK60 switch to Tier 4 and IMO Tier III was made with the addition of SCR aftertreatment and some improvements to the QSK60 engine. “One of the biggest changes is the fuel system,” said Jennifer McQuilken, Cummins global marketing communications leader, marine and oil and gas. “We are using a higher pressure fuel pump for a more efficient delivery of fuel.”

There’s also a redesigned piston, combined with the improved fuel delivery makes for better fuel combustion and “a cleaner burning engine with less particulate matter.”

The QSK60 also does not require a midlife top-end overhaul due to its filtration system.

“The cost of ownership is much better because you don’t have to do the top-end rebuild,” said McQuilken. An added bonus to designing the QSK60 to meet Tier 4 requirements is that maximum horsepower increased from 2,000 hp to 2,700 hp.

Everything isn’t always about high-horsepower diesels. Cummins 230-hp B4.5 is a good example. The B4.5, an in-line, 4-cylinder diesel, is a marinized version of the B4.5 industrial engine but delivers 16% more power and 11% more torque. The B4.5 also complies with Tier 3 emission regulations without the need of aftertreatment.

When looking at the inland waterways here and in Europe, Cummins “saw a need for an engine on the lower end of the power spectrum,” said McQuilken, whether it be for pumps or gensets, or a standalone unit such as the B4.5.

It is being field tested after repowering a tug engaged in dredge support work off North Carolina. Another B4.5 is being field tested as an auxiliary on an inland waterways pushboat.

A limited number of the B4.5 engines will be available in the third quarter, with full production scheduled for the fourth quarter. The QSK60 can be ordered now with delivery in the second quarter.